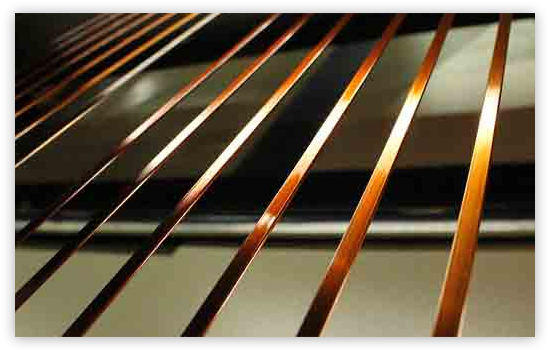

Enamelled Rectangular Copper Wires are used in low and medium voltage electrical machines such as motors, generators and transformers. The cross section of these wires ranges from 3.0 to 75.0 square millimetre with an insulation Class ranging from 105 to 220 degrees Celsius.Rectangular Enamelled Copper WiresPoly Vinyl Acetal, Class 105, 130Polyester, Class 130 and 155Polyesterimide 180Dual Coated Polyester (imide) + Polyamide imide, Class 200Polyamide imide, Class 200Polyesterimide Bondable, Class 155 and 180And Other insulation Coatings according to customer specifications

Product Range

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION STANDARD |

IEC-60317-17 NEMA MW-18C |

IEC-60317-18 | IEC-60317-16 | IEC-60317-28 | IEC-60317-29/ NEMA MW-36C |

IEC-60317-30 IEC-60317-47 NEMA MW-20C |

IEC-60317-58 draft) |

|||

| THERMAL CLASS | 105 | 120 | 155 | 180 | 200 | 220/240 | 220 | 120 | 180 | |

| Chemical base of base coat | Polyvinyl Acetal | Polyvinyl Acetal | Polyester | Polyesterimide | Polyesterimide | Polyimide | Polyamide-imide | Polyvinyl Acetal | Polyesterimide | |

| Chemical base of Top coat | Polyamide-imide | Epoxy-Bond coat | Epoxy-Bond coat | |||||||

| Range of Wire (Diameter) | Cross section area up to 80 sp.mm, Thickness : from 1.3-8 mm, Width : from 2.0-16 mm | |||||||||

| Insulation Range | IEC Grade 1:0.060-0.110, IEC Grade 2:0.120-0.179; NEMA Grade Heavy : Increase in thickness : 0.076-0.127, Grade Quadruple : increase in thickness : 0.127-0.178 mm |

In addition to base coat increase in dimensions, additional bond coat increase in thickness of 0.030-.0.050 mm |

||||||||

| Standard colour | Golden Yellow | Golden Yellow | Brown | Brown | Brown | Light Brown | Light Brown | Golden Yellow | Brown | |

| TECHNICAL PROPERTIES AS PER IEC-60317-0-2 |

||||||||||

| Flexibility & Adherence | ||||||||||

| :Mandrel Bending on thickness on width |

2-3 t & 3-4 W | 2-3 t & 3-4 W | 3-4 t & 4-6 W | 3-4 t & 4-6 W | 3-4 t & 4-6 W | 3-4 t & 4-6 W | 3-4 t & 4-6 W | 2-3 t & 3-4 W | 3-4 t & 4-6 W | |

| :Adherence (no crack after stretching %) |

15 | 15 | 15 | 15 | 15 | 10 | 15 | 15 | 15 | |

| Heat Shock No cracks after bending on thickness/ Temperature °C |

2-3 t/155 | 2-3 t/155 | 6 t/175 | 6 t/200 | 6 t/200 | 6 t/260 | 6 t/240 | 2-3 t/155 | 6 t/200 | |

| Break down voltage at Room temp. (minimum) Volts |

Grade 1 : > 1000, Grade 2: >2000 | |||||||||

| Resistance to hot transformer oil | Excellent | Excellent | Not applicable | Excellent | Excellent | Not applicable | Not applicable | Excellent | Excellent | |

| Heat Bonding temperature/Time | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | 110 C/48 h or 120 C/24 h | ||

| SPECIAL CHARACTERSISTICS & APPLICATION |

High mechanical strength, strong adhesion of enamel to copper conductor, Excellent hydrolysis & oil resistance |

Good thermal, and overall good mechanical, electrical and chemical properties |

High thermal, and overall good mechanical, electrical and chemical resistance |

High thermal, electrical and mechanical, properties, excellent heat shock and burnout |

Very high thermal properties |

Very high thermal properties |

Bondable coating with excellent mechanical properties |

Bondable coating with excellent thermal properties |

||

| Delivery Spools | Please refer to DELIVERY SPOOLS for Sizes & Respective Spool Types | |||||||||

| Special Notes | Oil filled power & distribution transformers, Inductance coils, etc. |

Oil filled large transformers Loco transformers, chokes & Inductance coils, etc. |

Large rotating Machines such as: motors,DC motors,High Voltage motors, etc. |

Large and special electrical machines such as: generators, alternators, Motors, HV motors, Dry type transformers, Inductor coils, etc. |

Special electrical machine and magnet coils for aerospace industry |

Large and special electrical machines such as: generators, Motors,HV motors, Dry type transformers, Inductor coils,etc. |

Oil filled large transformers, Loco transformers,chokes & Inductance coils, particularly with improved mechanical strength(hoop stress) to resist igh short circuit currents. |

|||

Engineering Data

Rectangular Wires

Cross Section area=wxt-0.8584 r² mm²

Where

W = Conductor Width in mm

t = Conductor Thickness in mm

And r = Corner Radius in mm

Weight of Copper Conductor

Weight in kg/km = 6.982 x d²

Where

d = Conductor dia in mm

and Copper density = 8.890 g/cc

- Conductor properties

- Nominal cross-sectional areas

Packaging

Delivery Spools

DIMENSION OF DRUMS (All dimensions in mm)

| Flange Dia |

Barrel Dia |

Traverse | Flange Thick |

Bore Dia |

Catch hole Distance | Slot/hole on barrel | No.of iron tube | Wt. Kgs. |

|---|---|---|---|---|---|---|---|---|

| 450 | 300 | 200 | 18 | 38 | 120 | 15 | 5 | 50 |

| 450 | 300 | 240 | 18 | 38 | 120 | 15 | 5 | 65 |

| 500 | 300 | 240 | 18 | 38 | 120 | 15 | 5 | 110 |

| 560 | 300 | 240 | 18 | 38 | 120 | 15 | 5 | 160 |

| 650 | 400 | 240 | 20 | 38 | 120 | 15 | 6 | 200 |

| 710 | 400 | 300 | 20 | 38 | 120 | 15 | 7 | 225 |

| 710 | 400 | 300 | 20 | 38 | 120 | 15 | 7 | 200 |

| 760 | 460 | 300 | 22 | 38 | 120 | 15 | 8 | 260 |

| 760** | 560 | 300 | 22 | 38 | 140 | 15 | 8 | 225 |

| 810** | 560 | 300 | 25 | 38 | 140 | 15 | 10 | 240 |

| 860** | 560 | 300 | 25 | 38 | 140 | 15 | 10 | 290 |

| 910** | 560 | 300 | 25 | 38 | 140 | 15 | 10 | 380 |

Note:

- Catch hole dia for all the drums will be 16mm.

- **One additional hole of 18mm to be provided on flande at 290mm distance from centre.

Ordering Info

We need the following information from our valued clients to understand fully your requirement and deliver the right product :

- Size : Width X Thickness

- Type of Insulation and thermal class, e.g. Polyester imide, Class 180 or Dual coated Polyester + Polyamide imide Class 200 or Polyurethane solderable, Class 155, etc.

- Grade of insulation (thickness), e.g. Grade 1 or 2 or 3, or Single, heavy or triple.

- Specification reference : e.g. IEC 60317-28 or IEC 60317-13 or NEMA etc. We can also supply as per Customer drawn Specification

- Packing : Spool size required (for specific Type please refer to Delivery Spools).

- Net Quantity : Quantity of Wire required, e.g. 2500 kg.(Minimum quantity at a time per size shall be either 1000 KGs or as mutually agreed upon)

For any other special requirement, please address your query to our Marketing Department in Mumbai by e-mail pinankwires@gmail.com